The bottom of the chicken cage is made of plastic floor. When the chickens are released, the plastic floor is pulled out, the chickens fall on the manure cleaning belt, and then transported to the disc outside the chicken house.

1. The bottom of the chicken cage is made of plastic floor. When the chickens are released, the plastic floor is pulled out, and the chickens fall on the manure cleaning belt, and then transported to the disc outside the chicken house.

2. Catching chicken disc: the structure design is ergonomic comfortable to catch chicken; the disk space is large so that the chicken does not stack and the wing folding rate is low.

3. Adopt mesh structure, no accumulation of feces, easy to wash; fixed outer plate, safe and firm.

4. With automatic feeding, drinking and manure removing, ventilation system and automatic control system, it can save energy consumption, improve labor productivity, reduce artificial feeding costs, and greatly improve the breeding efficiency of farmers.

|

Cage style |

Cage Size:(L*W*H) |

Birds/Cell |

Cells/set |

Tiers |

Capacity/Set |

Density/Birds(2.5kg) |

|

H type automatic harvest broiler cage |

3000*1800*600mm |

107 |

3 |

3 |

321 |

504.6cm2 |

|

H type automatic harvest broiler cage |

3000*1800*600mm |

107 |

4 |

4 |

428 |

504.6cm2 |

1. Drinking system includes the water pipes, water tank, water pressure adjuster, drinking nipples, Waterline front-end device, dosing system etc, choose according to customer needs.

2. Drinking nipples with cup can save water, keep the chicken manure dry.

3. The height of drinking line can be adjusted as the different chicken’s age.

1. Feed could be transferred from the silo to the main feeding line, then be transferred to the feeding machine. When the feeding machine is walking, feed will be sent into the feed trough, then chicken can eat it.

2. Mechanical transmission device running smoothly, low noise, long service life.

3. With the use of automatic control, the feeding system can adjust the amount of material.

4. Saving man power, saving feed, greatly improving the efficiency of Large-scale farming.

5. Feeding machine's speed is 10-15m/min.

Silo

Main feeding line

Feeding machine

Splint Feed trough

1. The chicken manure is conveyed to the horizontal manure removal belt at the end of the house through the vertical manure removal belt, and then it sent to the outside of the chicken house or directly to the truck through the oblique manure removal belt.

2. Each tier of chicken cages is equipped with a manure cleaning belt, the chickens are not in contact with the manure, the chicken manure is cleaned regularly, and the concentration of harmful gases such as ammonia and hydrogen sulfide is lower, which can improve the breeding environment of the chicken house and reduce the incidence of poultry diseases.

3. The manure removing belt we use is high quality PP material (polypropylene), which can be used for at least 10 years.

4. The walking speed is 2-4 meters per minute.

Automatic Manure removing system

Automatic Manure removing system

Horizontal and oblique manure removing system

Deliver to the truck

1. It has professional designed angle of the blade. After the dynamic balance test one by one, the blade can operate smoothly.

2. The air volume is consistent in the whole life of the fan. Bearings has advantage of high strength, low noise, durable and so on.

1. The cooling pad uses high-quality cooling pad paper and adopts space cross-linking technology, which has the advantages of high water absorption, high water resistance, anti-toxicity and long service life.

2. The cooling efficiency is over 80%, without surfactant, natural water absorption, fast diffusion speed and long-lasting effect.

3. The product does not contain phenol and other chemical substances that are easy to cause skin allergies. It is non-toxic and harmless to the human body and chicken when installed and used. It is green, safe, energy-saving, environmentally friendly, economical, and easy to install.

4. The frame aluminum alloy has high strength, good corrosion resistance, durability and beautiful appearance; Use a special filter for the cooling pad at the upper water to ensure clean water quality and support efficient water circulation components.

5. Combined with a negative pressure fan, it can effectively lower the indoor temperature.

The window is made of special selected high-quality engineering plastic, with high strength and long service life,together with superior anti-aging and anti-UV performance.

Function: Ventilation of the chicken house, usually used in winter.

This system can adjust the wind speed and direction, thus the cold air will not reach chicken directly, which can effectively prevent the phenomenon of cold stress in chicken.

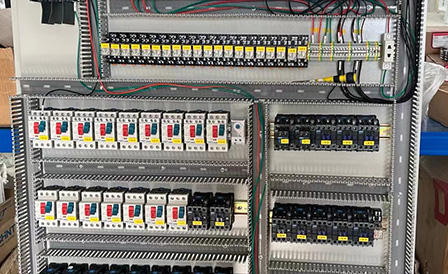

Environmental control system equipment is suitable for large-scale and intensive farming. According to customer requirements, we can provide various types of smart poultry equipment.

Our poultry management system is a modular system that manages all aspects of the chicken house, such as climate, temperature, humidity, ammonia, feeding, feed weighing, lighting and ventilation systems, and can monitor the situation of the chicken house in real time through a computer and mobile phone.

The management computer is the heart of the poultry farm, allowing you to easily monitor the entire poultry farm.