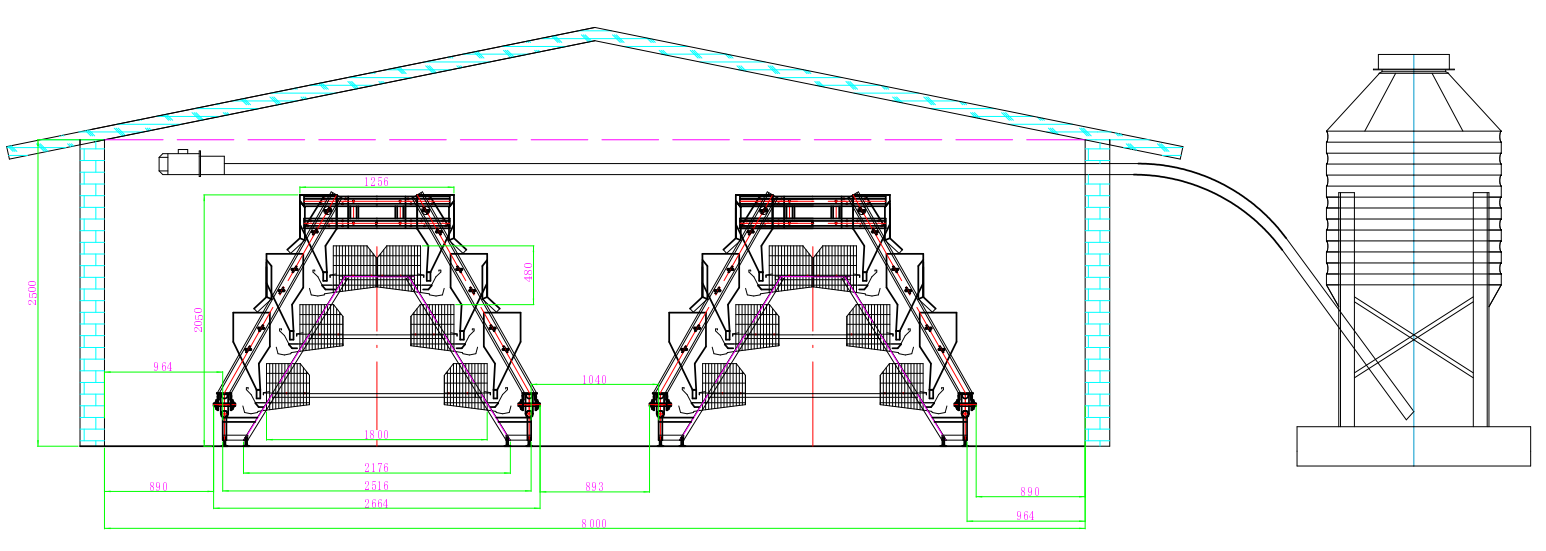

1. A-type layer cage is designed for raising laying hens. Suitable for hens aged 12 to 16 weeks, A-type laying hen cage is specially designed for raising laying hens. It is the best choice for farms with a breeding scale of 3,000-30,000 chickens.

2. The biggest advantage of A-type layer cage is its ability to increase egg production rates to an impressive 98%. Customers have the option to select a fully automated set of equipment, making operation simple and efficient.

MOQ (Minimum order quantity): 30 sets.

A type layer cage sytem is widely used in poultry chicken farming for low investment, high rate of return, long service life, and easy maintainance.Suitable for farms with a breeding scale of 3,000-30,000 chickens.A Type galvanized steel poultry laying hens chicken cage can be designed both open, semi-open and closed houses all over the world, which is suitable to be used in zone such as Africa, Southeast Asia, Central Asia, North America and South America Countries. At last, A type poultry layer cage has better ventilation performance than H type, more economical and practical.

1. Hot galvanized cage mesh with long service life and high stability can be used for 15-20 years. It also can provides a smooth surface to reduce the infection of parasites and helminths such as coccidiosis. The high-class material is also easy to clean and disinfect.

2. The tilt Angle of the bottom net (7°) is reasonable to ensure that the eggs roll out gently and the rate of breaking eggs is low.

3. Centralized cleaning of chicken droppings, feces thoroughly, improve the house environment.It is conducive to the prevention of infectious diseases in chickens.

4. Automatic feeding and drinking water system to reduce labor intensity, labor cost and feed loss. Applicable to artificial or semi-automatic and open chicken house raising.

5. To ensure maximum raising quantity according to good natural ventilation and environment. With the help of automatic climate control system, the ventilation effect is greatly optimized and the egg-laying rate is increased.

6. Scientific design of hen cage and hen cage house gives layer chicken a good environment with sufficient feeder, water, air, appropriate temperature and light to promote its growth and egg-laying rate.

7. Saving 75% of land compared to traditional chicken farming to maximize the number of breeding and productivity.

8. As customers requested to configure manure cleaning and feeding system to realize equipment installation and production. Low cost of the equipment, easy to operate.

|

Cage |

Cage Size:(L*W*H) |

Birds/Cell |

Cells/set |

Tiers |

Capacity/Set |

Density/Birds |

|

A type layer cage |

1950*350*380mm |

3 |

30 |

3 |

90 |

455cm2 |

|

A type layer cage |

1950*350*380mm |

3 |

40 |

4 |

120 |

455cm2 |

|

A type layer cage |

1950*450*410mm |

4 |

30 |

3 |

120 |

438.75cm2 |

|

A type layer cage |

1950*450*410mm |

4 |

40 |

4 |

160 |

438.75cm2 |

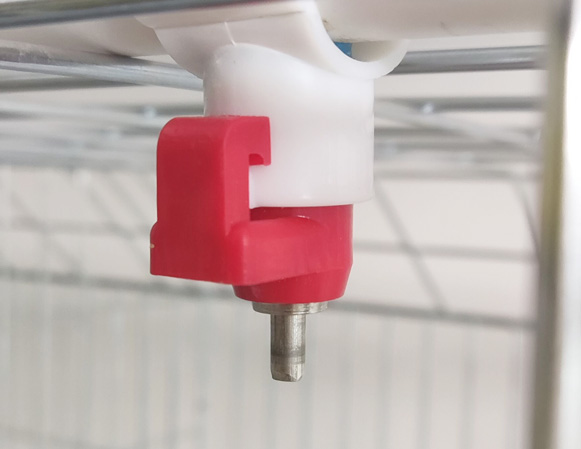

1. Drinking system include the water pipes, water tank, water pressure adjuster, drinking nipples, Water line front-end device, dosing system etc, choose them according to customer's needs.

2. High-quality water drinking pipes, pressure regulating valves and water drinking nipples can effectively prevent the water leakage. And drinking system adopt the closed piping system, which can minimize the water pollution.

3. 360° drinking nipples provide adequate drinking water for poultry at all stages.

4. The automatic drinking water system mainly adopts the steel ball drinking nipple. lt uses imported high-grad stainless steel, POM resin, and APS engineering material, which is wearing resistant, and the durability can be used for long time.

1. Automatic feeding machine can be chosen between gantry and ladder feeding machine. Gantry type feeding machine is a relatively economical and practical machine with simple operation, remote control walking character, easy to manage.

2. Mechanical transmission device running smoothly, low noise, long service life.

3. With the use of automatic control, the feeding system can adjust the amount of material.

4. Feeding with arched structure, high carrying capacity, not easily deformed.

5. Saving man power, saving feed, greatly improving the efficiency of Large-scale farming.

6. The walking speed of gantry feeding machine is 9--12 m/min.

Ladder feeding machine

Gantry feeding machine

Silo

Main feeding line

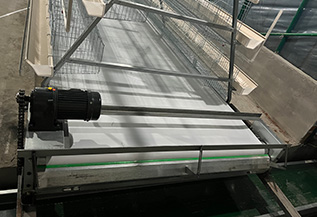

1. Manure removing system included scraper type and conveyor belt type, Which can reduce the labor intensity and labor cost, keep the chicken shed dry and clean.

2. A type chicken cage can use scraper type or conveyor belt type.

3. The scraper type is suitable for A type cages, which can clean two or three rows. For the starters, this type is a good choice. lt can not only save some labor cost, but also save some investment in the whole project. The cleaning speed is 6-10 meters per minute.

4. Conveyor belt type is more suitable for large scale farming. The manure removing belt we use is high quality PP material (polypropylene). The walking speed is 2-4 meters per minute.

Automatic Scraper Manure Removing System

Automatic Belt manure removing system

Automatic Belt manure removing system

Horizontal and oblique manure removing system

1. Eggs can be buffered before rolling onto the egg collection belt, which can effectively reduce the number of broken eggs.

2. The horizontal egg feeding part can effectively filter broken eggs and soft-shell eggs to avoid mutual contamination during egg collection.

3. Eggs can be delivered to the egg operation table according to customer requirements, or directly to the egg storage.

4. The system is stable and reliable, and the broken egg rate is low.

5. The walking speed is 5-6 meters per minute. Take the 80 meters chicken house as an example: the eggs can be collected in 20-30 minutes.

1. It has professional designed angle of the blade. After the dynamic balance test one by one, the blade can operate smoothly.

2. The air volume is consistent in the whole life of the fan. Bearings has advantage of high strength, low noise, durable and so on.

1. The cooling pads uses high-quality wet curtain paper and adopts space cross-linking technology, which has the advantages of high water absorption, high water resistance, anti-toxicity and long service life.

2. The cooling efficiency is over 80%, without surfactant, natural water absorption, fast diffusion speed and long-lasting effect.

3. The product does not contain phenol and other chemical substances that are easy to cause skin allergies. It is non-toxic and harmless to the human body and chicken when installed and used. It is green, safe, energy-saving, environmentally friendly, economical, and easy to install.

4. The frame aluminum alloy has high strength, good corrosion resistance, durability and beautiful appearance.

5. Use a special filter for the cooling pad at the upper water to ensure clean water quality and support efficient water circulation components.

6. Combined with a negative pressure fan, it can effectively lower the indoor temperature.

The window is made of special selected high-quality engineering plastic, with high strength and long service life, together with superior anti-aging and anti-UV performance.

Function: Ventilation of the chicken house, usually used in winter.

This system can adjust the wind speed and direction, thus the cold air will not reach chicken directly , which can effectively prevent the phenomenon of cold stress in chicken.

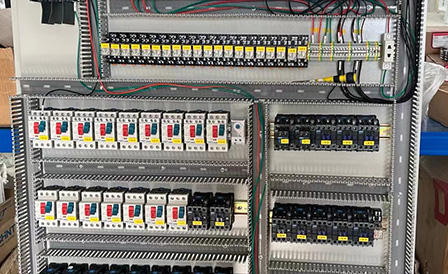

Environmental control system equipment is suitable for large-scale and intensive farming. According to customer requirements, we can provide various types of smart poultry equipment.

1. Our poultry management system is a modular system that manages all aspects of the chicken house, such as climate, temperature, humidity, ammonia, feeding, feed weighing, lighting and ventilation systems, and can monitor the situation of the chicken house in real time through a computer and mobile phone.

2. The management computer is the heart of the poultry farm, allowing you to easily monitor the entire poultry farm.